Tokin, as an arc welding torch manufacturer, is uncompromising with made in japan quality.

The welding of metals is essential for many industries and our welding torches and robot

peripherals are sold not only in Japan but around the world.

The TokinArc® trademark is sold domestically in Japan through nearly 200

distributors and internationally starting with North America, Europe, India, China, SE Asia,

Oceania, South America, South Africa, and

expanding to other regions around the world. Our products are used in automobile production,

electrical equipment, steelmaking, and shipbuilding among other fields.

Welding, which supports all industries including automotive, steelmaking,

shipbuilding, aircraft manufacturing, atomic energy, and space exploration, undergoes

changes in needs depending on environmental and technical

requirements. Therefore, Tokin delivers the appropriate depth and breadth of products with

variation and customization necessary to meet our end user's unique objectives and welding

conditions.

Welding, depending on the joining method, is classified into the following three

categories. “Fusion” when a base metal is heated and melted with or without a filler

metal to then solidify and create a bond, "Pressing" when mechanical pressure is used to

create a bond, and "Brazing" when a bond is created only by melting a filler metal but

not the base metal. Tokin focuses on a method of fusion known as “Arc Welding”,

specializing in arc welding torches and related equipment.

Today with automation advancing in many fields the use of computer-controlled robotic manufacturing

systems are increasing. At Tokin the demand for “robotic torches” and “robot peripheral equipment” is

growing.

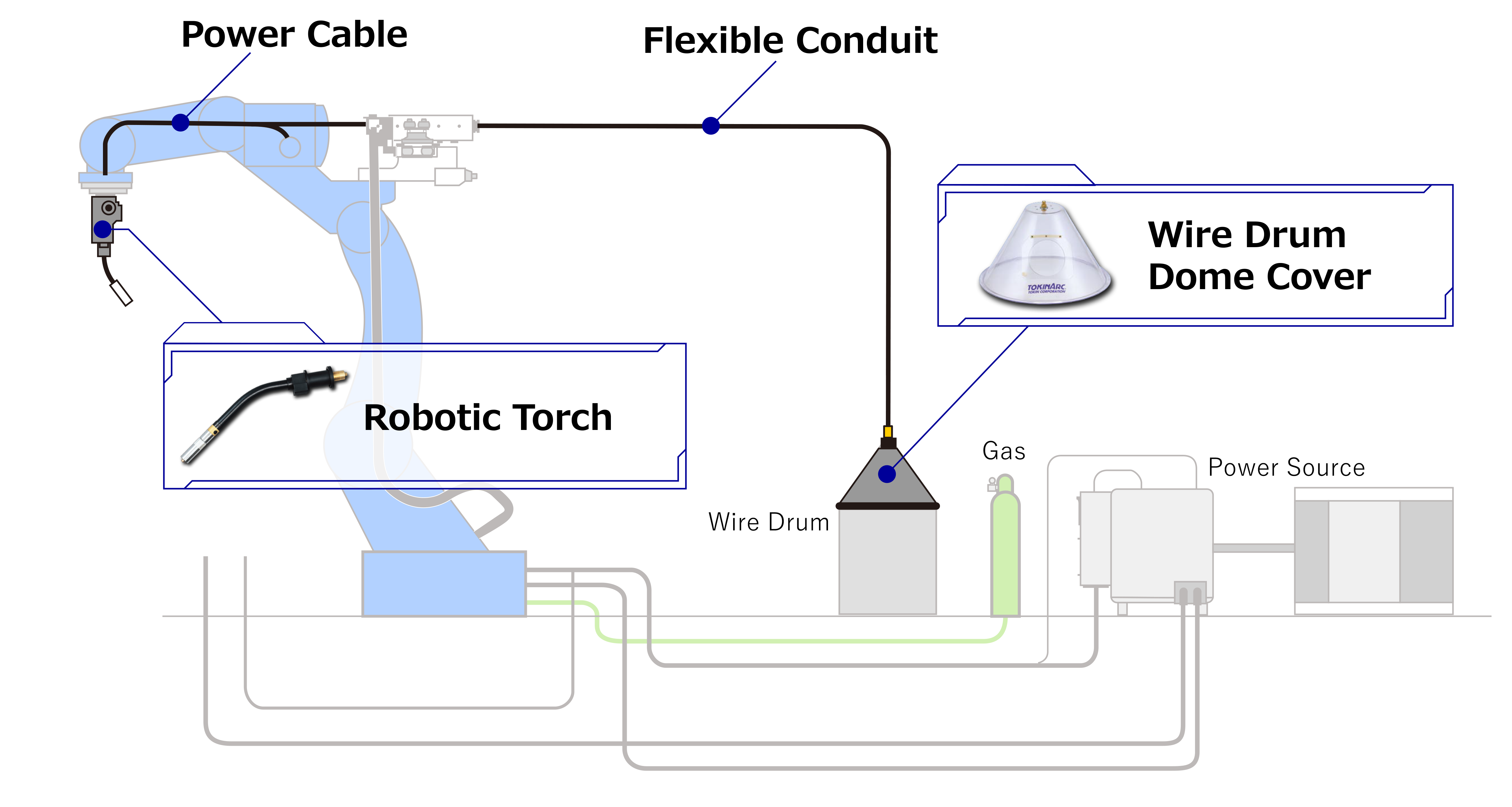

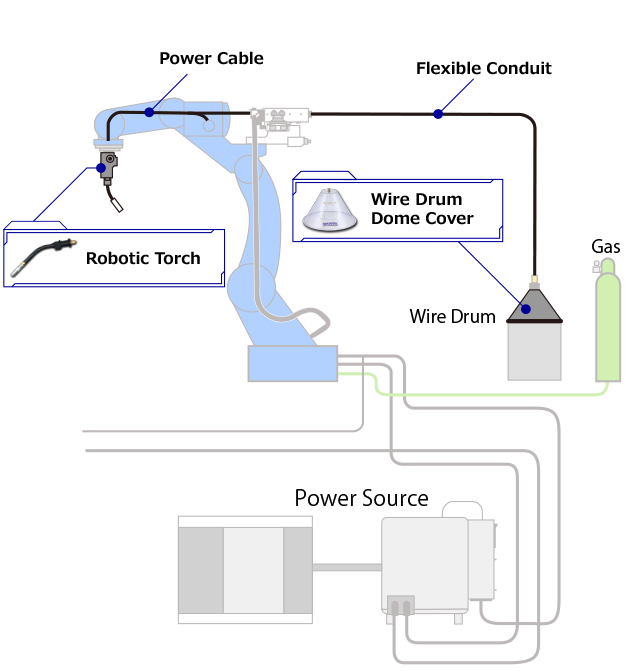

The standard composition of an industrial arc welding robot system is illustrated in the above drawing.

Depending on the welding method a power source, welding torch, wire feeder, and other devices are

adjusted to meet the welding requirements and utilized.

Tokin, as a torch specialist, manufactures torches which mount to the end of the robot arm and are

durable enough to run in automatic welding operations. We supply power cables and flexible conduits

compatible with all types of wire

feeders.

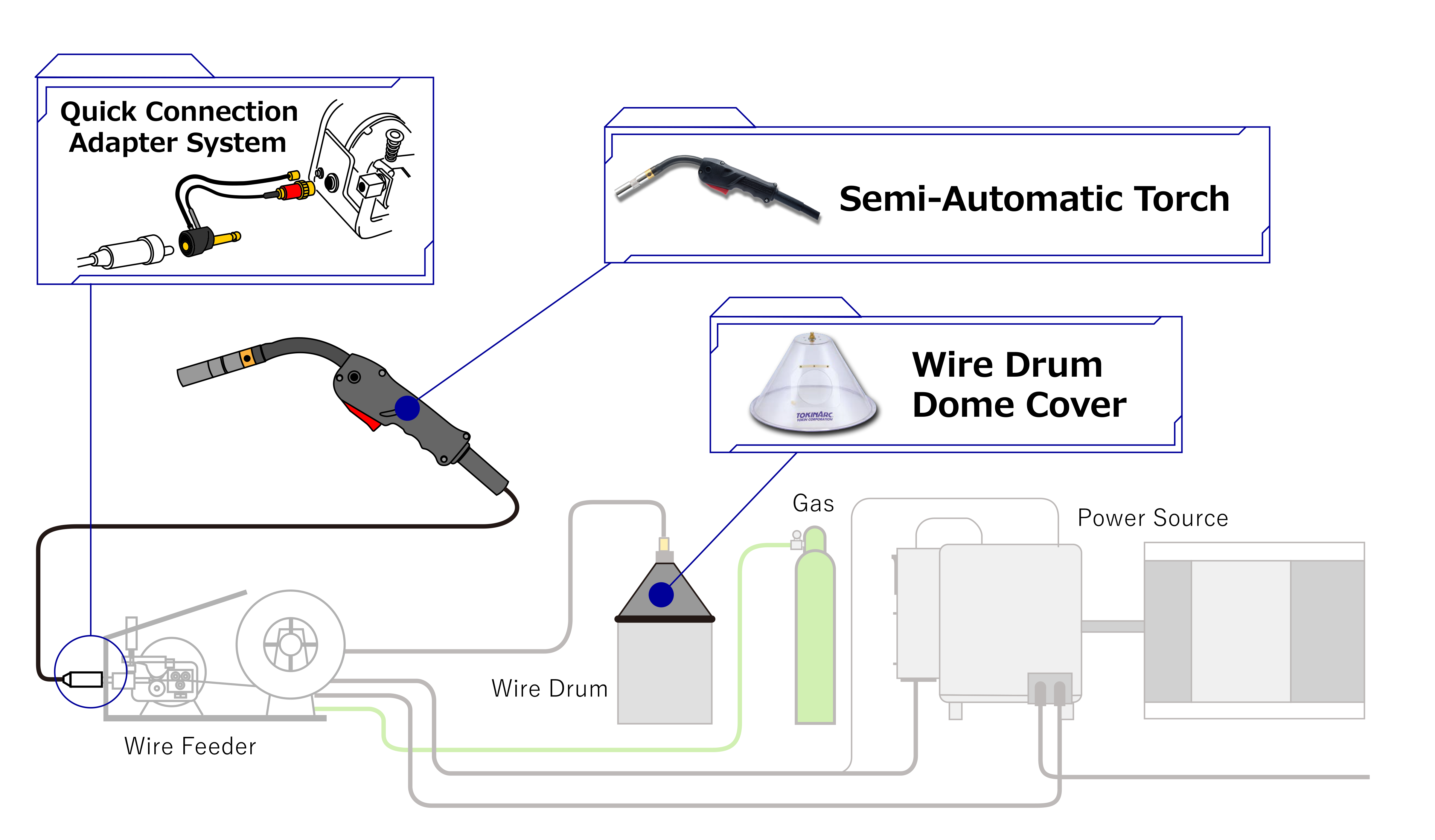

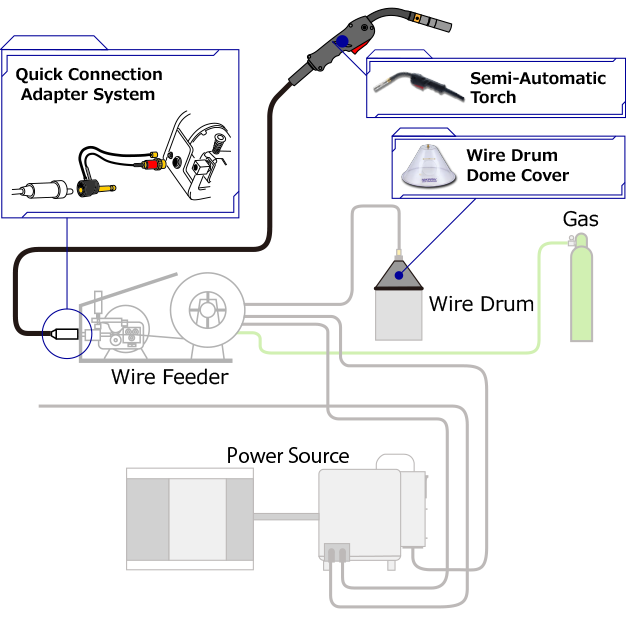

In semi-automatic welding several kilowatts of power are supplied by the power source and travel through

not just the torch but the wire, wire feeder, and wire spool. In addition to electricity, through the

torch hose shielding gas is supplied from a

gas tank to the welding point. The power source precisely controls the wire speed. Our company

manufactures semi-automatic torches, wire drum dome covers, and quick connection adapters.

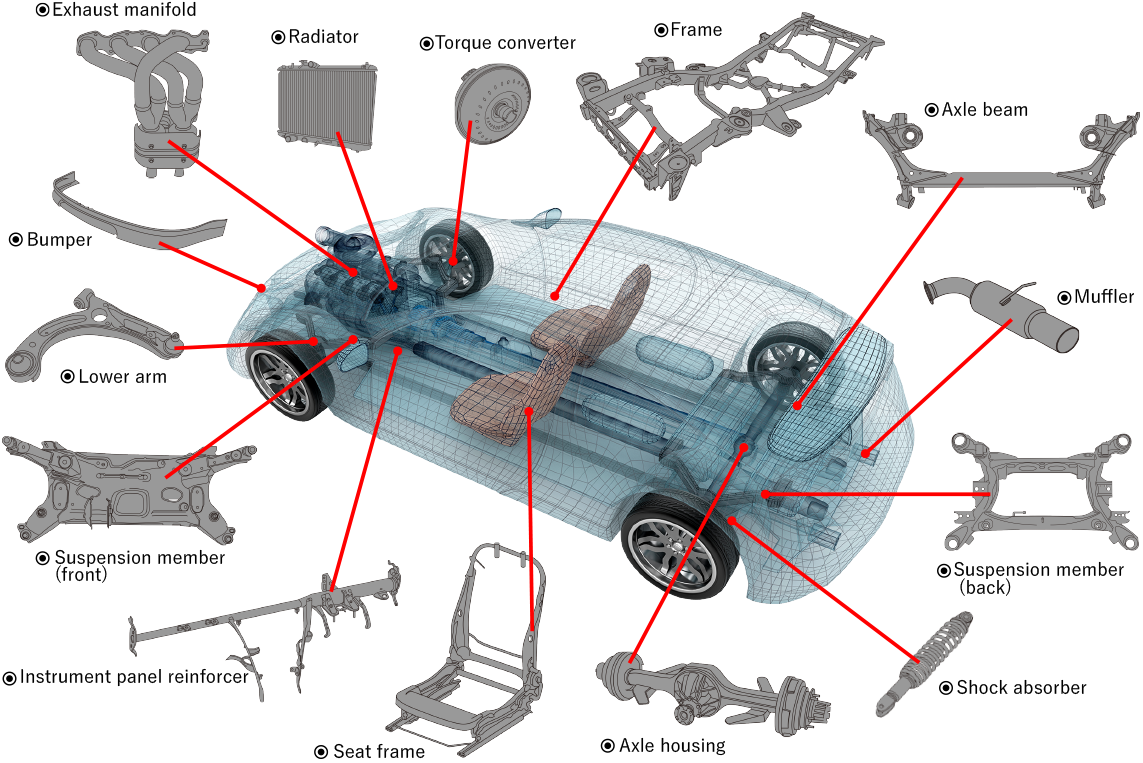

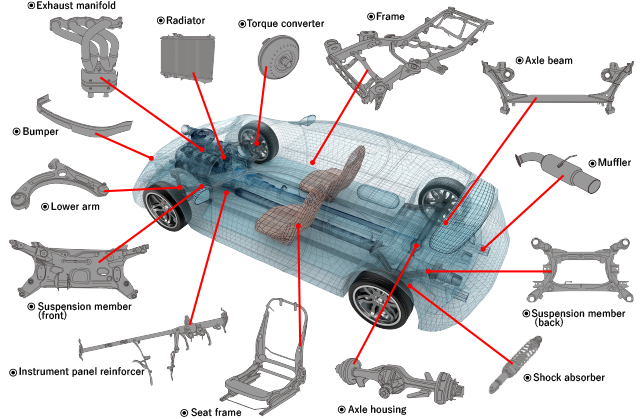

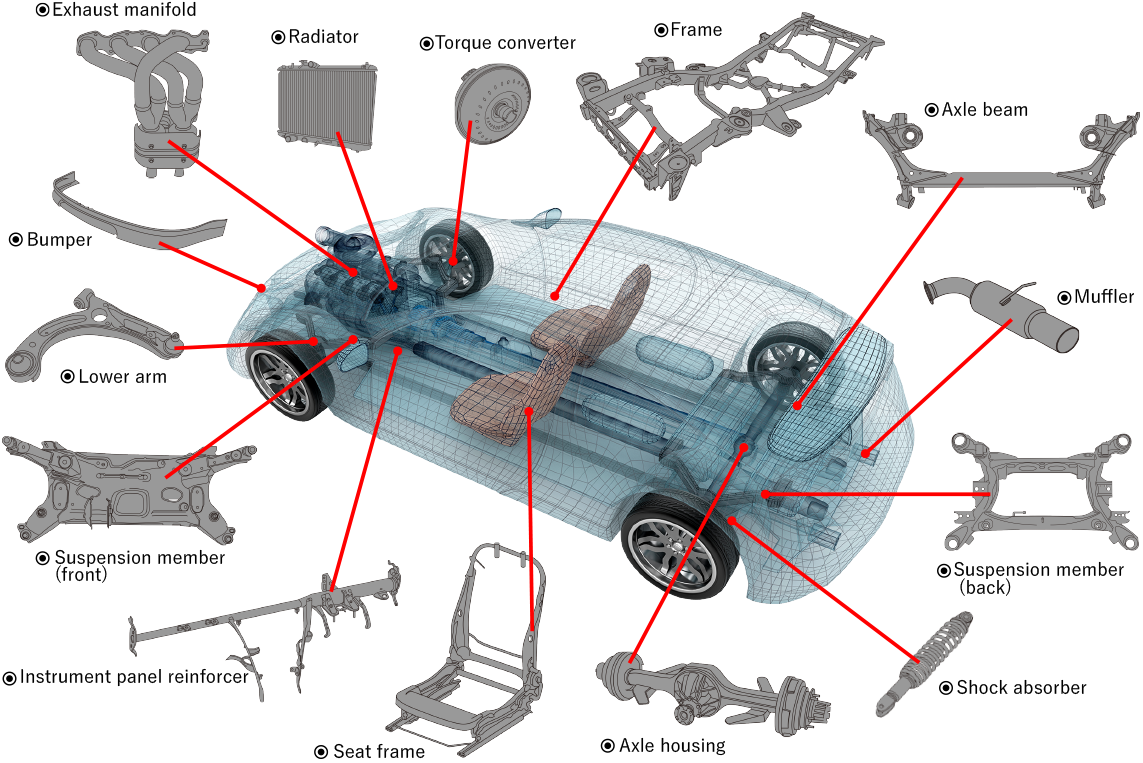

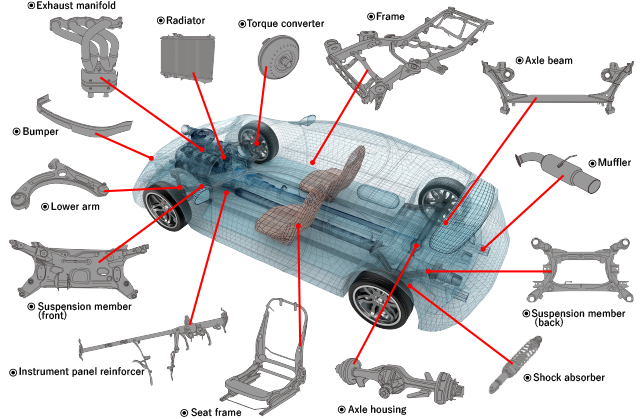

Starting with the automobile industry and continuing into transport aircraft, welding materials and

methods appropriately suited for varying types of steel such as galvanized and stainless are being

utilized. If you look at the accompanying figure can

see that welding is used for every part. Our company's TL series, air-cooled robotic torches, and TIG

welding torches are being used in automobile production.

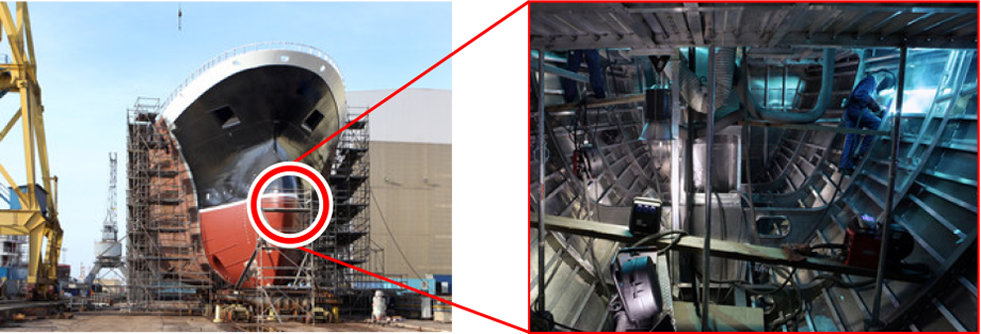

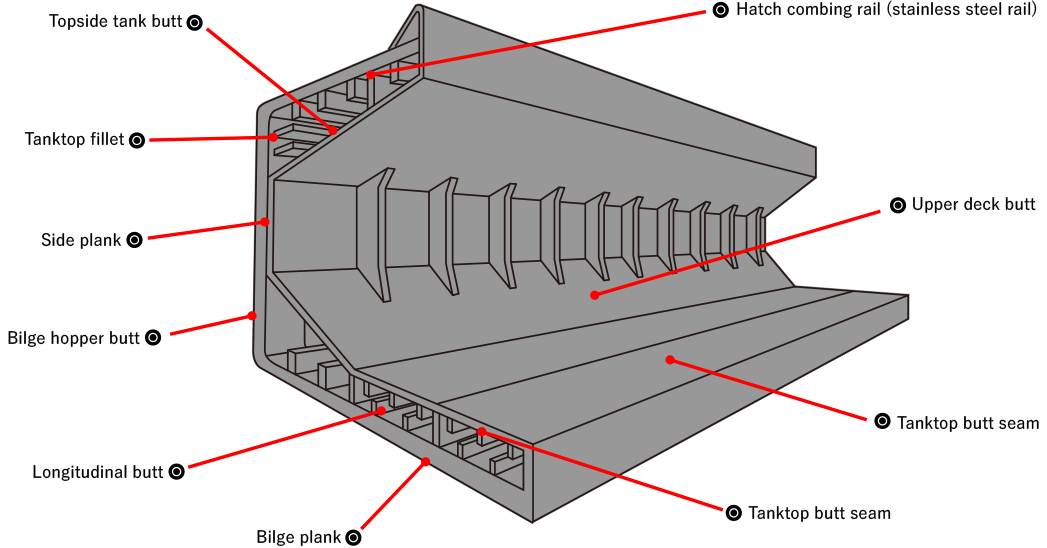

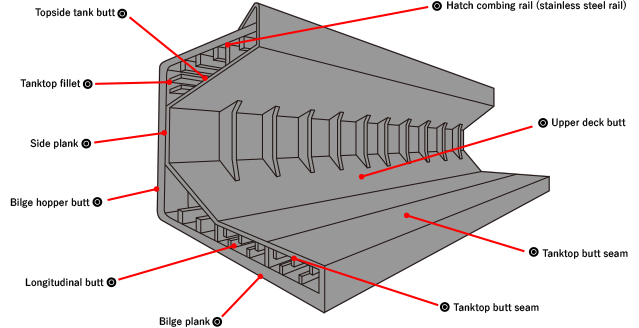

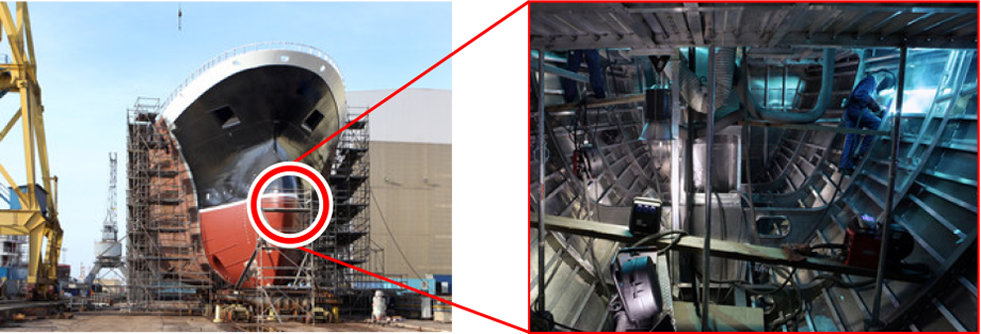

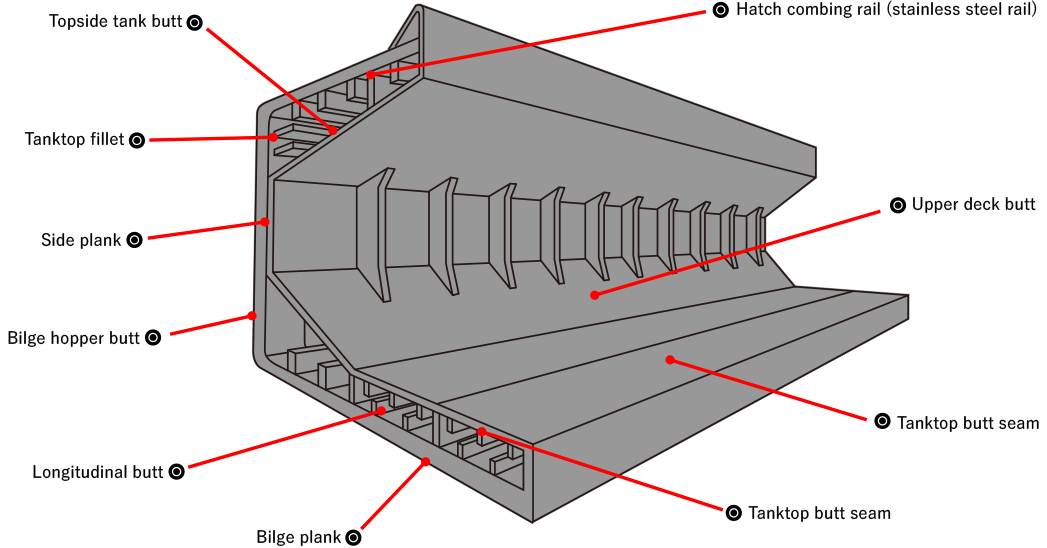

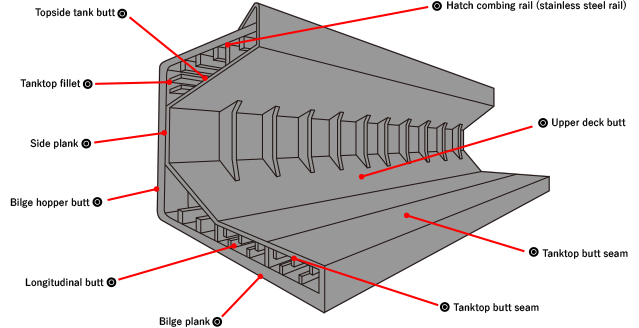

In the production of a large steel ship in Japan, the welding of the bilge using semi-automatic torches

is commonplace. However, as in the below figure a system called the "hull block construction method

(HBCM)" is also widely used. In addition, since

this process utilizes large machine tools in indoor block assembly plants, computer-controlled gas

plasma torches and similar devices are further realizing efficiency and accuracy. Robotic welding

systems are utilized in large sections

called panel lines, where in particular efficiency is advancing. Our company's TL series, CSH series,

and air-cooled robotic torches are being used in shipbuilding.

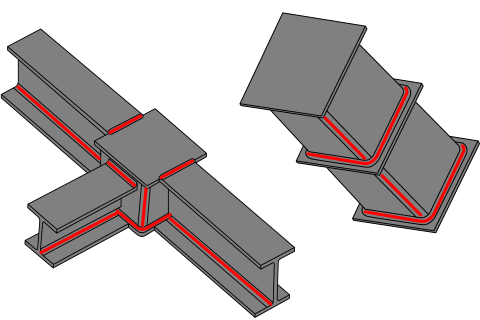

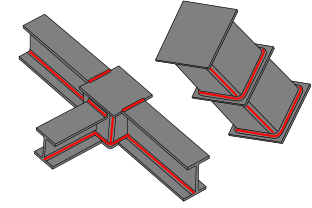

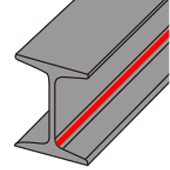

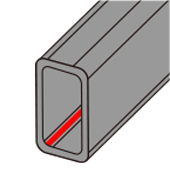

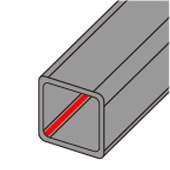

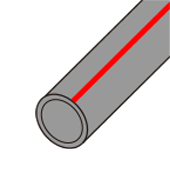

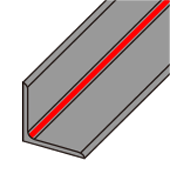

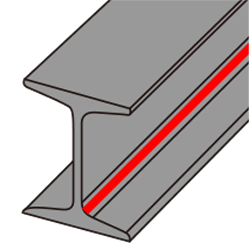

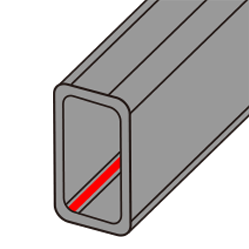

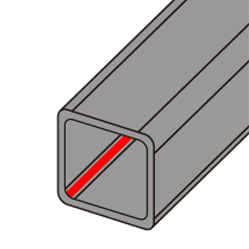

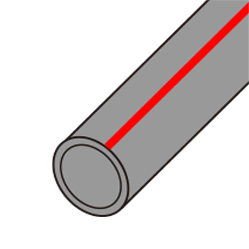

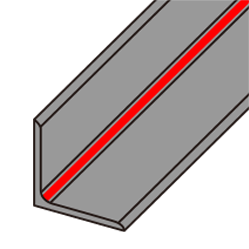

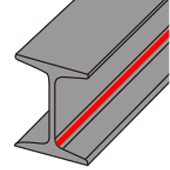

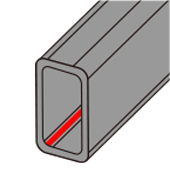

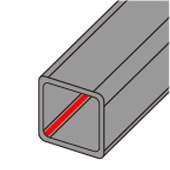

In the construction of high-rise buildings or similar steel frame structures, shapes such as "H",

"rectangular pipe", "round steel", and "L" are welded in large quantities. The welding technolgy for

steel frame structures demands high-quality and efficiency,

including earthquake-proofing. Our company's TL series, CSH series, and air-cooled robotic torches are

being used in steel frame construction.

H-shaped steel

Rectangular steel pipe (short type)

Rectangular steel pipe (box type)

Round steel

L-shaped steel

H-shaped steel

Rectangular steel pipe (short type)

Rectangular steel pipe (box type)

Round steel

L-shaped steel

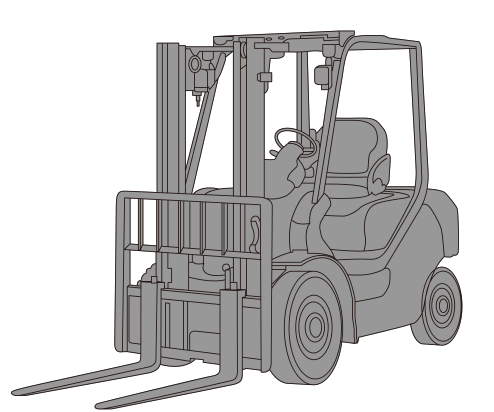

Construction machinery and special vehicles such as shovel cars, wheel loaders, bulldozers, and

forklifts are utilized in industries all over the world. The welding technology for this equipment

demands high-quality and efficiency. Our company's water-cooled

robotic torches and water-cooled semi-automatic torches are being used in construction machinery

production.

Construction and Mining Machinery

Forklift

Construction and Mining Machinery

Forklift

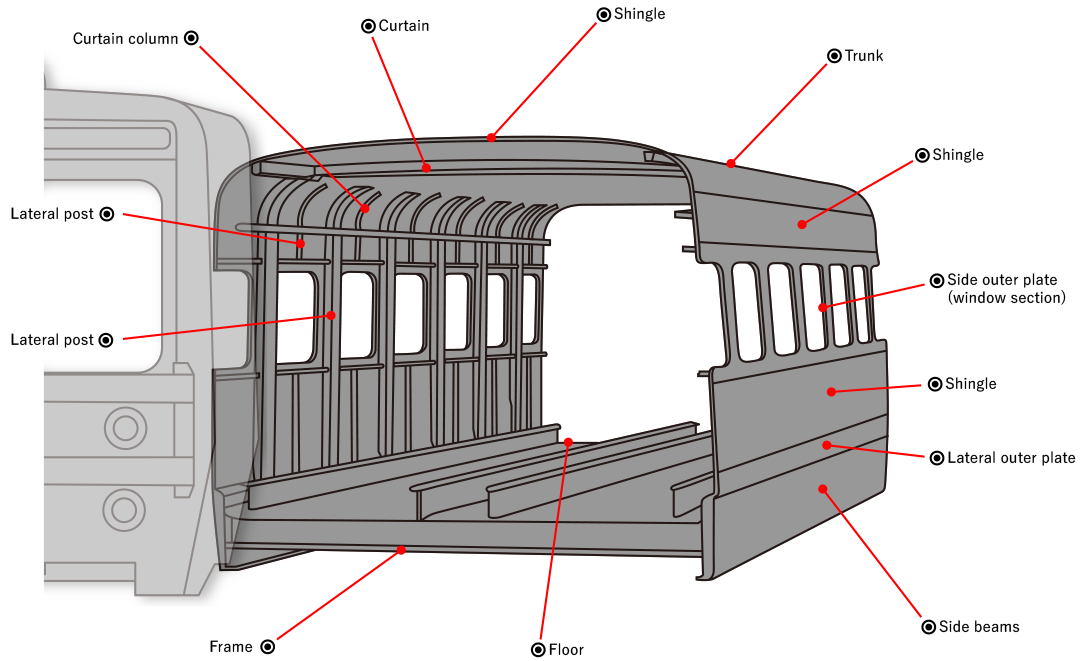

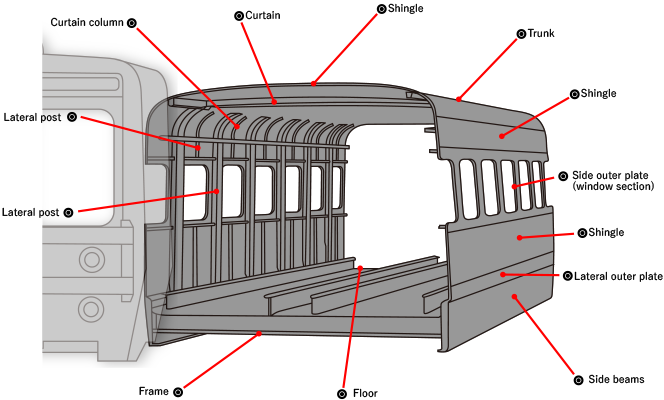

Welding has become an indispensable industry for railway vehicles such as high-speed, subway, non-stop,

and cargo in-use all over the world. Roofing, flooring, and lateral steel plates are welded together

with base frame, pillars and eaves. Our company's

TL series, CSH series, and air-cooled robotic torches are being used in railway vehicle production.